Historically glass is obtained with sand and broken down minerals, such as sandstone and quarzite for the silicates, and the ashes and burnt plants or mineral soda made up the alkalis: sea shells found in the sand provided the necessary calcium to make the glass less soluble in water. The secondary elements consisted of various oxides and metals added to change the colour of the glass.

Blowing

Blowing technique revolutionized the production of glass objects; indeed, it reduced working times, and brought with it the widespread use of glass objects, which until that time had been done so only by the elite who could afford to do so.

After drawing up a design, the glassmaker would gather up the fused glass gob with a blow-pipe and keep it rotating on a metal plate, the so-called “bronzin”, so as to define its proportions. This stage was very important for the following blowing because it made the glass even and compact, something necessary to the correct expansion of the surfaces. The gob was then lengthened with tongs, by rolling it with a rod that was mounted on the work table, and then went on to the blowing process: this is carried out both by modelling and through the use of instruments with different times and methods depending on the object to be produced. Once the “container” was blown, it was reheated and in the meantime the glassmaker begins working on related handles and legs required. Once these latter details were finished they were attached with heat onto the body of the container, making sure of their alignment and symmetry, and then the entire object was reheated.

Mould blowing is usually used to give objects special shapes.

A working technique that dates back to the 16th century is that of “crackle glass”, which created objects with irregular surfaces full of fissures, while still maintaining its transparency. The effect was obtained by putting the semi-finished product from blowing in cold water and immediately reheating it so as to close up the surface fissures. Once the surface effect was stabilized, the piece was blown and modelled into the desired shape.

Among the typical techniques from the 20th century, let us look at “incalmo”, “pulegoso glass” and “overlaying”.

Filigrana

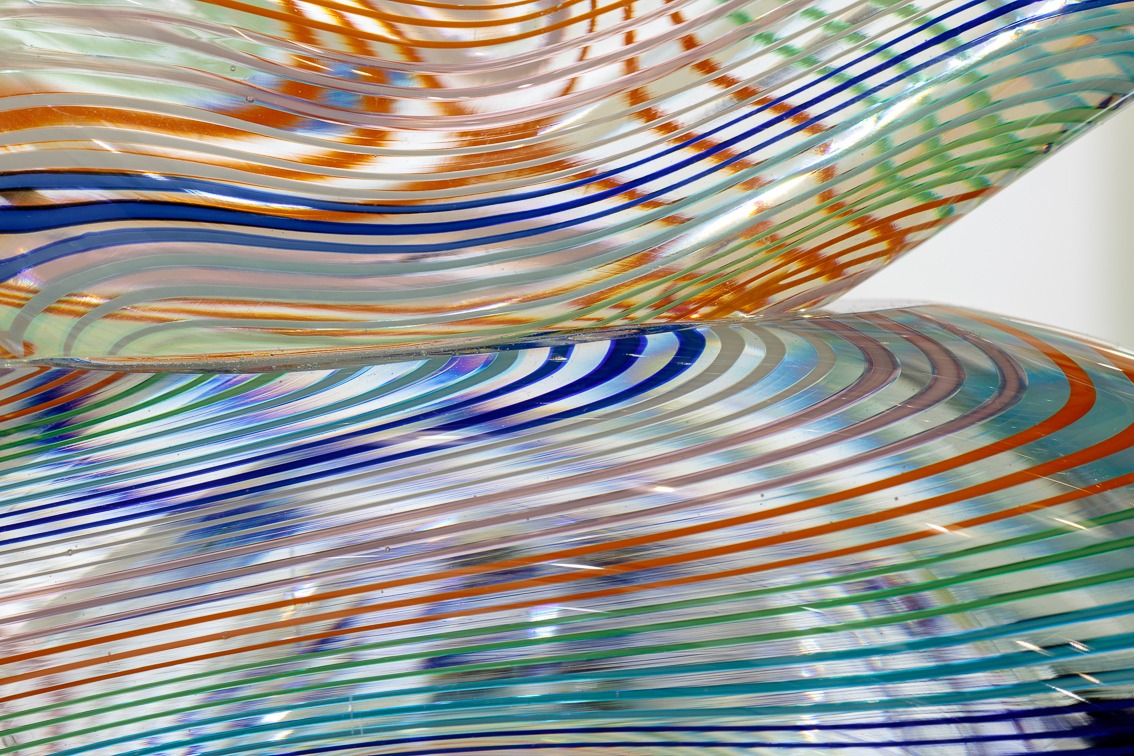

The most refined decorative techniques is Filigrana, or Filigree caneworking.

The filegree effect is obtained by starting with normal gob of glass that is going to be blown together with rods of threads of coloured glass and lattimo. These are formed by drawing the gob of coloured glass or lattimo and then modelling it on the bronzin slab until it forms a cylinder. It is subsequently dipped into a crucible containing founded transparent glass, to be modelled on the bronzin slab again. Following this, a second cane is attached to the end away from the “canna di levata” or extracting rod, and two glassmakers pull the canes in opposite directions so as to stretch the gob of glass into a long rod form, which has a coloured centre and an outer transparent cover. After cooling, the rods are cut into the diesired lengths and are placed side by side on a plate that is placed in the oven until it reaches fusion point: the plate is taken out and the gob of transparent glass that has been modelled on the bronzin slab is rolled over it so that it attaches itself to the outer surface. This cylinder covered with glass rods is heated again and remodelled on the bronzin slab until it is pinched at one end and goes onto blowing.

Variations of filigree glass are “filigrana a reticello” and “a retortoli” with their network effect.

The first is obtained starting with two cylinders covered with canes that are slowly twisted in opposite directions and thus intertwined and blown, so that the overlapping of the two deformed filigrees going in opposite directions form a fine network effect.

The “a retortoli” effect is carried out along the same procedures of the first technique, but starts off with canes filled with coloured glass that have been twisted together within each other. These canes are made with lattimo and coloured glass: according to the final design they are placed on a refractory plate, heated and a gob of glass previously modelled on the bronzin slab is rolled over the canes. As with the “a reticello” procedure the two glassmakers then pull in opposite directions while turning it at the same time.

Murrina

Another tecnique very used is the murrine glass.

The procedures to make murrine glass start off with the same canes described for filigree: an initial gob that will be the core of the cane is modelled on the bronzin slab into a cylindrical shape, and then it is covered with a layer of differently coloured glass which when put into a mould has a cross-section in the form of a star. More layers are added and modelled until the desired symmetry is reached, which is followed by the final application of another layer. The cylinder as such is continually modelled on the bronzin slab and then a glass cane is fused to one end of the cylinder which gets pulled in opposite directions by two glassmakers until a long cane with a minimum diameter is formed, while leaving the internal design intact. The cane is then cut into cross-sections with a height of 10 to 20mm to make the murrines. These disc-shaped objects form the base of the composition of the final artefact: they are carefully selected and cleaned, placed on a refractory plate, and in the remaining spaces between each disc are filled with pieces of glass canes and are then placed in the oven until the entire composition fuses together.

Vetro Cristallo e Lattimo

Two Venetian glass products from the 15th century are crystal and lattimo.

Crystal is a material that is particularly transparent, as created by the Venetion Angelo Barovier: its transparency is obtained by using very pure raw materials.

Lattimo is a milky opaque glass which was obtained by adding lime to a mixture of lead and tin. Nowadays calcium and sodium fluoride crystals are added to give it its opaque aspect as the latter are dispersed during cooling.

Calcedonio

Another opaque glass product is the so-called “chalcedony”. This glass was made by bringing a mixture of opal and transparent glass fragments to the point of fusion, and afterwards silver nitrate is added to the fused mixture, along with cobalt oxide, potassium bichromate and other salts. Once everything was added the fused mixture was brought to working temperatures and the products created looked like siliceous minerals, or as mentioned chalcedony, which was used as an decorative stone.

Avventurina

Avventurina is a transparent glass in which copper crystals are evenly distributed during the cooling of the fused mixture. It seems that the product was discovered by accident, through an error in the preparation of the mixture. Given the difficulty of creating a shiny metal effect of quality, its creation was considered as the Italian word suggests, an “adventure”, or “gamble”, which is why the product has this name.

Vetro Ghiaccio

A technique dating back to the 16th century is the “crackled glass” process, a type of glasswork whose surface is irregularly covered with cracks while still maintaining its transparency. This effect is achieved by immersing the semi-finished piece from the blowing process into cold water and then immediately reheating it to close the surface cracks. Once the surface effect is stabilized, the piece is blown and worked until the desired shape is achieved.

Typical 20th-century techniques include incalmo, pulegoso glass, and sommerso glass.

Incalmo

Incalmo is a technique that permits the creation of pieces composed of two different pices of different colours: the two single elements are modelled separately and then joined, using an “incalmo”, where they are attached and fused along the edge. This technique is very delicate because the the final fusion point must not be visibile, and as such the two pieces must be modelled so that they fuse together perfectly.

The overlaying technique

The overlaying technique is ideal for creating pieces with elevated thickness so as to confer a sense of depth to the object. A first glass gob is modelled and blown to give an elementary form of the final shape, and then it is immerged in a crucible containing transparent glass and is taken out to drip off the excess. The piece is modelled and if desired, applications can be used and then it can be newly coated and blown. The pieces play off transparency and colouring of the final layers for a relief effect and one of depth.

Il vetro pulegoso

Pulegoso glass is opaque due to the very high concentration of bubbles of different sizes; it is made by adding organic substances that decompose and release gas bubbles.